Full Answer

How to stabilize hardwood floors?

Oct 02, 2020 · Stabilized Wood Maintenance: Oiling and Waxing - The Vape Snob The costs of running this huge site are paid for by ads. Please consider registering and becoming a Supporting Member for an ad-free experience.

How much does a stabilized wood mod cost?

Jan 18, 2022 · With Epoxy Resin. If you are working with softwood, then using epoxy resin is a great idea to stabilize the wood. When mixed with hardener, epoxy resin will form a hard layer to cover the surface of the wood and keep it safe. For best …

What is stabilizing wood?

Jan 27, 2022 · What Is Stabilized Wood? Stabilized wood is a material that has been treated in a way to improve its durability, appearance, or sound/vibration characteristics. Stabilized wood is used in many fields. The most common application is musical instruments, but it also finds practical use in furniture, cabinets, and boats, among others.. Stabilized wood is used so …

Why do stab wood mods sell out so fast?

Jan 15, 2022 · If you’re looking high-end stabilized wood or hybrid stab wood mods, you’ve come to the right place. My mission is to list all the best stab wood mods right here with pictures, price range, tech specs and where you can get them on a single page.. When I wanted to get a stab wood mod, I realized how terribly inefficient the whole HEMO (high-end mod) segment really is.

What can I use to stabilize wood?

Wood is stabilized when resin or wood hardener is injected into a piece of soft or rotted wood, causing the wood to harden. Other substances can also be used to stabilize the wood such as resin epoxy, thermosetting resin, and a vacuum chamber.

How can I stabilize wood for cheap?

Resin is one of the most popular and economical wood stabilizers. The resin stabilization process involves drying the woods then putting them in vacuum chambers to remove all air pockets. This drying process is especially necessary if you're working with green wood (newly cut wood).May 31, 2021

How do you stabilize soft wood for turning?

1:359:41How to Stabilize Wood and What is Stabilization - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnother option I've used a few times is using a penetrating epoxy this is one from total boat andMoreAnother option I've used a few times is using a penetrating epoxy this is one from total boat and this is a much thinner epoxy.

How do you stabilize wood at home?

Wood stabilization is the process of strengthening wood so that it will no longer respond to changes in humidity. Stabilization can be performed in five steps: drying the wood, loading the vacuum chamber, saturating the wood with resin, curing the wood, and coloring the wood.Apr 26, 2021

How can I stabilize wood without a vacuum?

The way to do this is to cook the wood at 220° F for a minimum of 24 hours. Then take the wood out of the oven and immediately place it in air tight containers or ziplock bag until it is cool enough to stabilize. Second, make sure your oven temperature is 190-200° F when curing your blanks.

How do you use cactus juice stabilizing resin?

Quick Start Basics for UsePrepare blanks.Place blanks in vacuum chamber and weight down.Add Cactus Juice to completely cover blanks.Apply full vacuum to chamber and keep your vacuum pump running until bubbles stop.Release vacuum and soak blanks for at least twice as long as you had them under vacuum.Remove blanks.More items...

What is Cactus Juice stabilizing resin?

Cactus Juice Stabilizing Resin is a premium, professional grade, heat cured resin for stabilizing and hardening wood and other porous material. It is especially effective on those beautiful, punky, spalted woods that are just too soft to work with!

What resin do you use for wood turning?

Orthophthalic resins are the most economical and widely used. It has a tendency to be more brittle than epoxy, but this depends heavily on the agents the resin is combined with. In general, beyond the smell, polyester resin is a wonderful choice for woodturning projects.

Is Cactus Juice stabilizing resin food safe?

in order to do so, certain FDA tests would have to be done which would be cost prohibitive so, the answer is NO, it is not listed as food safe. However, once cured, Cactus Juice is an acrylic similar to Plexiglas.Jul 10, 2012

Does wood absorb resin?

Does Epoxy Resin bind to Wood? Yes, epoxy resin generally sticks to nearly all surfaces. The thinner the resin, the more likely it is to penetrate the pores of the wood and bind to it.

Does stabilized wood need a finish?

You don't have to apply a finish to stabilized woods. You need only sand the work piece with a succession of 100-, 320-, and 400- grit abrasives, and then buff with a compound to bring out a deep sheen.Oct 21, 2013

How do you stabilize a wooden structure?

How to stabilize Wood – Stabilise wood the right wayWood, as a material, is incredibly versatile. ... Thermosetting resin allows complete penetration of the wood used and thus ensures the best possible stability. ... Epoxy resin can be used to stabilize and repair wood in a way that is sufficient for many applications.More items...•May 11, 2020

What is wikihow similar to?

wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, volunteer authors worked to edit and improve it over time. This article has been viewed 45,322 times. Learn more... Wood products change and warp depending upon the temperature and humidity.

How to make wood stronger?

Shake the wood hardener can well. Pour it on a disposable bristle brush in a size that will reach all parts of the wood that needs to be stabilized. Saturate the area with the product. Apply several coats in succession to improve the strength of the wood.

How long does it take for pentacryl to dry?

You will see the top of the wood start to darken from the inside out as it absorbs the wood stabilizer. Keep it saturated for two to three days, or up to a week with very large cookies. Move the wood cookie to a drying location once all the Pentacryl is absorbed.

What is the pentacryl method?

Use the Pentacryl method if you have a fresh piece of wood that is in the process of drying. A “cookie” or cross-section of wood can be successfully treated with precautions taken to keep it drying at a steady rate.

How many times has wikihow been viewed?

To create this article, volunteer authors worked to edit and improve it over time. This article has been viewed 45,322 times.

How to keep wood from sticking to bottom of pool?

A Tupperware is perfect for a small piece, while a kiddie pool covered in a drop cloth works great for large cookies. Place wooden slats or “stickers” at the bottom of the pool to keep the wood off the bottom.

How to keep wood from flaking?

Separate three egg yolks from egg whites. Mix the egg whites in into the solution to reduce flaking. Create a stand on which to hold your wood cross-section upright. Apply a thick coat of paste to both sides of the cross section. You want the moisture to be dried from both sides simultaneously.

What Do You Mean By Wood Stabilizing?

Wood is not always very hard, and softwood can easily be damaged. Hence, wood stabilizing becomes necessary to ensure that they last long and remain protected from moisture. To create a stable and hardened piece of wood, you will need to inject softwood with resin.

How To Stabilize Wood?

If you are working with softwood, then using epoxy resin is a great idea to stabilize the wood. When mixed with hardener, epoxy resin will form a hard layer to cover the surface of the wood and keep it safe.

What Types Of Wood Can Be Stabilized?

All types of wood cannot be stabilized as they do not have equal absorbing capacity. However, there are certain types of wood that come with larger pores, and these work the best. As the pores are bigger, the density is lower, making the wood perfect for stabilizing.

What Is Stabilized Wood Used For?

Craftsmen and artisans who work with wood often stabilize wood before using them to make items. If you are wondering what stabilized wood can be used for, think of all the things that you would use good quality wood for.

How To Stabilize Wood Frequently Asked Questions

In this section, we will be listing down some of the frequently asked questions about stabilizing wood. This should help in clearing up your queries too and hence, read through carefully.

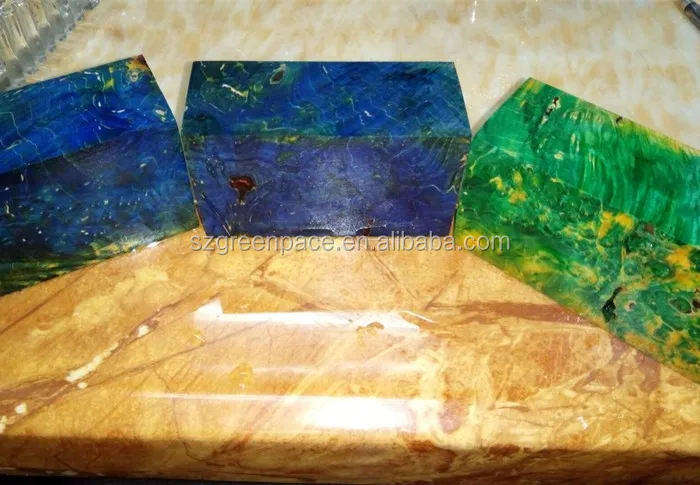

What Is Stabilized Wood?

Stabilized wood is a material that has been treated in a way to i mprove its durability, appearance, or sound/vibration characteristics. Stabilized wood is used in many fields. The most common application is musical instruments, but it also finds practical use in furniture, cabinets, and boats, among others.

Why Do You Need To Stabilize Wood?

Wood is a natural material that is not as durable as many people are lead to believe. Wood can be prone to various environmental and biological issues. These include rot, termites, cracks/splits, and insect attack (by carpenter ants, for example).

What Can Stabilized Wood Be Used For?

Stabilized wood has numerous uses. It can be used to replace conventional wood, to upgrade it, or even to make entirely new products from the material. From musical instruments to furniture, cabinets, and boats.

How To Stabilize Wood With Epoxy Resin

Now that you know what stabilized wood is and why you want to use it, it’s time to learn how to make it yourself. The easiest way to stabilize wood is with epoxy resin. Here are the steps you need to follow:

Vacuum Chambers For Stabilizing Wood

Vacuum chambers are used for stabilizing wood because they reduce shrinkage during curing, which reduces the weight and bulkiness of the wood while making it more durable. There are two types of vacuum chambers: hard-end gravity vacuum chamber and soft-end gravity vacuum chamber.

How To Stabilize Wood With Thermosetting Resin

Stabilized wood can also be made using a thermosetting resin. They are used in the same way as epoxy resin except that thermosetting resins can’t be sanded or scraped off, so they are better suited to treating large surfaces, such as the deck of a boat, for example.

JB Woodworks

Evan Ripple from JB Woodworks make all types of mods, but the stabwood squonk mods are really hot right now.

Sohers Mod Design (SMD)

Ghost Dragon is one of the newer designs from SMD, but they are always creating new freehand designs. They now also make stabwood squonk mods.

Carlos Creation

One of the most sought-after devices, Carlos Creation puts the bling in your mod with a tons of accessories. The cream of the crop, stab wood mods are just a part of their entire high-end catalog. Sales is via their FaceBook group.

Axis Vapes

Based in the United States, Axis Vapes sells through a proper website and unique reserve-checkout system, where you can easily find the mod you want. No rafffles, X1 or other crap. The pictures are very accurate.

Mellody Mods

The Mellody Box is an iconic mod, with a minimalist design. Sales are through pre-orders announced in the FB Group.

Dendro Mods

The wood bodies are machined by hand with no help of CNC. All sales are done 1 at a time through this page. Sales are by X1 quickstrikes or randomizers.

DPM Mods International

Based in Philippines, they make the Nataraki mod as well as other high-end non-wood mods and squonkers. Sales is via the FaceBook group or page by batches.

Why does Wood need to be stabilized?

Any craftsman will assert that hardened wood is best to work with. When we set out to use wood that is hard, we can create almost anything effortlessly. The objects that we create from this hardened wood will look good, and the quality of the wood is clear from the end result of the product we created.

What can be created from Stabilized Wood?

Why do craftsmen go through this entire wood stabilization process? Surely stabilized wood means that better products can be produced. Stabilized wood can be used to make everything we would generally craft from good quality wood. This includes bowls, pen handles, knife handles, dishes, and all wooden necessities that we need daily.

What Type of Wood can be Stabilized?

The truth is not all types of wood can be stabilized or they do not stabilize well. The best type of wood to be stabilized is the wood with large pores and a low density. The reason why wood with large pores can be stabilized rather easily is that the large pores allow the wood to absorb most of the stabilizing medium.

The Stabilization Process

To stabilize softwood, the thermosetting resin can be used. The reason we use resin is to penetrate the softwood completely. In fact, thermosetting resin penetrates the wood not only on the surface, but the heat soaks into the wood impregnating the wood as well.

How to stabilize Wood with Thermosetting Resin

Thermosetting resin means an oven is used to cure the resin. 95 degrees Celsius is the oven temperature required. Drying wood at 104 degrees Celsius can be left to dry in the oven for 24 hours before the stabilization process.

How to ensure that you are ready for the Stabilization Process?

The first step for the stabilization process is actually preparing for the process.

Getting everything into the Vacuum Chamber

The initial step to using a vacuum chamber is to lay the wood blanks that need to be stabilized in the vacuum chamber. During this process, the wood blanks may float away. It is vital to ensure that the blanks do not float off. An anti-float mat is one alternative that can be used to keep the blanks down.