How do you fix a broken stator coil?

FYI: The stator coil generates the power for the spark plug and other accessories on small engines Without a stator there would be no spark at all, meaning the engine won't run. While a stator is dying, it can produce a weak spark, causing the engine to miss or run poorly. Symptoms are often worsened as the engine warms up.

How do you tape the stator coils?

Step 3: Star or Delta Windings. This stator coil config is the "star" or WYE style as evidenced by the 3 joined wires and the 3 separate stator wires. Simplified explanation is that star gives more voltage and delta gives more amps for a given rpm. Since we want more volts at a lower rpm it stands to reason we will configure our stator windings ...

How do you rewind a stator?

· Delta on the left, Y on the right. Consider the "R" the coil on the alternator. Our single phase alternators are similar to the Delta in wiring, BUT, we do not draw power from the three points in the Delta (N1,N2,N3). In our alternators, the delta is opened. More of a U, and we just draw power from the two open ends of the U.

What happens when a stator coil dies?

· First, pull out the old paper out of the slots in the stator using a pair of pliers or tweezers and make sure the empty slots are free of debris. Then, measure the width of the slots and cut a sheet of insulation paper into strips of the same width. Fold the strips gently and slip them into the slots in the stator individually by hand.

How do you wrap a stator coil?

2:5522:24How to Rewind & Repair a 3 Phase Motorcycle ATV UTV Powersports ...YouTubeStart of suggested clipEnd of suggested clipSort of three separate places where they're attached you'll generally find somewhere a spot whereMoreSort of three separate places where they're attached you'll generally find somewhere a spot where three the three coils joined together and it's insulated.

Can a stator be rewound?

Stators produce electrical current by spinning coils of copper wire, wound around individual heads, through a series of brushes. If any of the individual wire coils become damaged, most commonly from overheating, the damaged stator heads must be rewound with new wire.

How do you wind a stator coil?

Remove the terminal clips from the damaged wires using a screwdriver. Unwind the damaged wire from the stator and clean the surface with a lint-free cloth. Wind the new copper wire as a coil using the same gauge as the wire already on the stator. Coil it tight to remove spaces or gaps between the wires.

Can you overload a stator?

You can actually burn the stator and rectifier by overloading it. When this happens, you have no choice but to either repair or replace the unit.

Is it possible to repair a stator?

If repairing a stator is outside of your skillset or you would rather get a new stator, a full replacement is possible. You can either perform the installation yourself or outsource the whole process to a reliable ATV repair expert.

Can a stator be rebuilt?

In many cases a new stator is the safest, most cost-effective solution for an electrical system breakdown. Because repairing stators can be an intricate and detail-intensive process, replacing failed stators with an entirely new part can be a much easier route, depending on the specific motorcycle.

How do you wind a coil by hand?

4:436:39A COIL WINDING JIG - YouTubeYouTubeStart of suggested clipEnd of suggested clip1.More1.

How do you wind a magnetic coil?

Wind the magnet wire around 2 inches of plastic tube, cut from a straw or a pen casing. Leaving 1 foot of wire free, wind the wire around the tube, starting at one end and working your way across to the other. The coils should be neatly wound, and tightly packed together.

How do you wind a small coil?

0:501:48How to Wind a Wire Coil with a Power Drill - YouTubeYouTubeStart of suggested clipEnd of suggested clipUse one hand to squeeze the trigger on the drill. And the other hand to very gently and slowly feedMoreUse one hand to squeeze the trigger on the drill. And the other hand to very gently and slowly feed the wire back and forth along the length of the tube.

Can a bike run without a stator?

The stator coil generates the power for the spark plug and other accessories on small engines Without a stator there would be no spark at all, meaning the engine won't run. While a stator is dying, it can produce a weak spark, causing the engine to miss or run poorly.

What causes a stator to burn out?

That high voltage spike can punch through the enamel insulation in the stator coils and cause them to short out. This “inductor kick” is how the spark in an ignition coil is generated from 12volts. Not many people realize the spark is created when the current through the coil is switched off.

Why do stators fail?

When a stator fails, it is largely due to the degradation or aging of its insulation through external occurrences and materials being introduced into its system.

Step 1: Pull It Apart

This is relatively simple, 3 long bolts and the case is apart. Then remove the field connection brushes from the rear of the case, it has the letters F and N on the connector, being field and neutral. Once everything is apart, check the bearings for wear, they should turn freely without noise of grinding.

Step 2: Ripping Out the Old

I'll start off with the caution. The wiring varnish/shellac has sharp edges, so be careful when removing the old windings. The original windings were 13 turns of 1.2mm dia and I reduced the wire diameter to 0.75mm in order to double up on the windings, fitting in 30 turns in each stator slot.

Step 3: Star or Delta Windings

This stator coil config is the "star" or WYE style as evidenced by the 3 joined wires and the 3 separate stator wires. Simplified explanation is that star gives more voltage and delta gives more amps for a given rpm. Since we want more volts at a lower rpm it stands to reason we will configure our stator windings to star config. If your stator had only 3 connection wires with 2 wires joined on each connection, then you would have a delta connected stator..

Step 4: Sliding in the New

By the way, I salvaged the enamelled copper wire from an old fridge motor, for what its worth. In this 3 phase 4 coil wind in 24 stator slots, we start by inserting the 1st coil and skipping 2 slots for the other 2 phases. Even the start wire (lead in) and the exit wire (lead out) are separated by 2 slots as can be seen in the pics below. 120 degree phase separation mistake. It has been pointed out to me that my phases haven't been wound with a 120 degree separation, more like 60 degrees, which will most likely result in low voltage output. I should have left an empty slot between the lead out wires, so a rewind will be necessary to correct this mistake..

Step 5: New Rethink

I decided to add slot-insulation just in case of a wire short to stator edge or something else. So I used Ganex DMD 2-3-2 0.18mm which is half the price of the Nomex stuff yet still good till 150 degrees C. DMD stands for Dacron-Mylar-Dacron, for what its worth. I also used a "D profile" fibreglass rod called a topstick to keep the wires in the stator slots. Lastly the windings are treated with a shellac or varnish to keep them in place and also to prevent loose wires from vibrating which might cause shorts etc..

Step 6: 120 Degree Phase Separation Rewind

I decided to rewind the stator with the correct 120 degree phase separation and check performance before jumping to any conclusions. The exit wires to the diode pack need a 1 slot spacing between them for the 120 degree phase power output.

Step 7: Closing Up

First install the Diode pack, then once the diode pack is installed, the end coil wires can be soldered on. Slide the rotor in to check for fit, nothing touching or scraping, and then the front case half can be installed. Lastly install the brushes for the field rotor coil and hook up all spade connectors and plastic covers. The N Neutral conn is used as a voltage sense for the regulator, the F field goes via the alt warning light on the dashboard to the regulator. The case is connected to batt neg and the big threaded rod from the diode pack goes to the batt positive..

What is the R on an alternator?

Delta on the left, Y on the right. Consider the "R" the coil on the alternator.

How many coils are in a Delineator 450?

For the winding pattern, I'm going to replicate what Delineator did on his 450: two separate windings, joined together in parallel, consisting of 3 coils each, with each coil alternating CW and CCW. I'm aiming for 60 windings per coil, but will try to squeeze on more if possible.

Does a permanent magnet alternator have brushes?

Yendor: No brushes on a permanent magnet alternator....The excited field ones have brushes. Interestingly, Honda figured out how to do the excited field without brushes, gives the best of a PM alternator in simplicity (no slip rings or brushes to wear out) with the best of a regulated output that the excited field puts out.#N#That's something a lot of people don't understand about the PM alternator. the output is not regulated, just prevented by load from going over 15 volts. . The excited field adjust the output to match the load. The PM basically adjust the load (regulator is a shunt ot ground, adding load when volts are above 15) to keep the volts from climbing too high. The problem is they never really know if the battery is charged, so if they are working well, they overcharge the battery. So most motorcycles have a system that is sized very slightly larger then the maximum load, so that they just don't overcharge the battery too much.#N#To the OP question, your diagram is correct on the single phase. It looks like on the 450 the coils are split evenly, 3 and 3 for lights on/ light off...On the 350 and 360, they are split 4 coils, and 2 coils. 4 for lights off, 6 for lights on. On the 76 model CB360t, the USA type had to have headlights on all the time, so the alternator was jumpered in the harness to be 6 coils at all times. The on/off switch for the headlight was eliminated too...

Can you cure coils in an oven?

both of the above have to be cured to reach these above properties, this can be done in an oven as the curing temps are fairly low. you could maybe use one of these thicker types to coat the bare framework first, but then you would still need something else when you are done to get the coils done. commercial shops dip the completed assembly into the epoxy and let it soak into it completely getting all the air out. I did not have enough of the epoxy to do that, so i repeatedly poured small amounts on the assembly from both sides letting the excess run through and over the coils until i was satisfied that each coil had most if not all of the air within it replaced with epoxy. this would be impossible with the thicker stuff.

Why do coils have to be wound CW/CCW?

Since the rotor is circular, every other coil is exposed to north, and the other coils south. To keep the polarity of the electric the same, the coils have to wound CW/CCW to match the alternating polarity of the magnets. Otherwise the new output would be zero, as each coil cancels out the other.

Is a CB360 a single phase alternator?

The CB360 and 350 and your 450 there also are single phase alternators. No delta or Y. The three phase alternators are either delta or y. In delta, the three phases are connected end to end in a circle, schematically looks like a triangle . Y has one side of each coil connected together, schematically looks like a Y.

Does a stator work?

my stator works great. no issues at all, it is a bit of a painstaking process, biggest thing is to not nick or ding or wrap the motor wire across any metal edges etc. dont want it to short and the covering on the wire is very thin. i used the high voltage kapton tape as well because my core had some bare metal areas.

How to force armature out of stator?

Force the armature out of the stator by hand. Once you’ve removed the upper endplate from the motor housing, guide the armature straight out the bottom of the circular stator, along with the attached lower endplate. You'll encounter some resistance from the magnets around the stator, which means you may have to push a little harder than you might expect before it will give way.

How to rewind a motor?

To rewind an electric motor, remove the motor's outer housing and use your hands to pull the armature out of the stator. Then, use a flat head screwdriver to pry open the tabs on the brush pads, and then cut through the wires and pull them out by hand. Once you have the coil off of the armature and stator, wind a new wir e of the same thickness and material into the armature. Be sure to coil the wire the same number of times to ensure a proper fit for conductivity, and secure the coil with tabs before reassembling the motor. For tips on identifying the coil pattern and handling the motor during disassembly and assembly, scroll down!

How to fix a faulty motor winding?

Cut the old windings free using a pair of wire cutters. Depending on the type of motor you’re working on and where the problem lies, the faulty windings may be found on either the stator or the armature. Snip each coil of wire where it connects at the top of the protruding posts.

How to loosen a brush pad?

Use a screwdriver to pry open the tabs on the brush pads. Wedge the tip of a flat-blade screwdriver underneath the thin metal tabs, then pull up gently on the handle to lift them enough to loosen the coiled wire. On some motors, there may be as many as 12-16 tabs in total.

Why do you wear gloves on stators?

Wear gloves to protect your hands and avoid transferring the oils from your skin to any part of the stator or armature .

Where are the windings located on a motor?

The windings are long coils of copper wire typically located around the stator. They channel electromagnetic energy into the rotor to cause the motor to turn.

What is the armature of a motor?

The armature (also known as the “rotor”) is a small bearing-like piece in the center of the motor construction. When it receives the magnetic force of the stator and windings, it spins, powering the motor. The windings are long coils of copper wire typically located around the stator.

Why isn't my spark as strong as it should be in a cylinder?

even though it has decent spark outside of the cylinder , it may not be as strong as it should in the cylinder because the atmospheric air is a lot less compressed than in a cylinder.

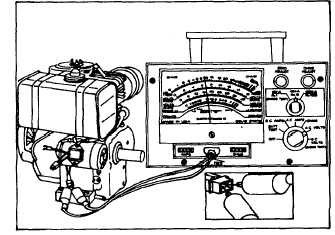

Can you measure voltage coming out of a stator?

You can't really measure the voltage coming out of the stator with any simple piece of test equipment. The stator would only put out a short pulse and the meter would be expecting the voltage to be reasonably constant so that it can take its time with the measurement.

How to get a stator out of a mold?

Use a chisel or a screw driver to gently pry around the lid untill it breaks loose. Once the lid comes off you can usually turn the mold upside down and the stator will just fall out. If not then turn the mold upside down and tap on it with a hammer or pry gently at the edge of the stator. It should come out easily.

How to clean burned insulation off a wire?

Let the wires cool down, and then clean the burned insulation off carefully with sand paper.

Do all 3 coils have to be the same side up?

Be sure all 3 coils are same side up (the start of the coil is the wire that crosses over the inside, and it should be facing up - you need to be sure that no coils are 'upside down'. We are about to wire up 1 phase of the alternator.

Do coils fit well?

Even though the coils fit well and are the right size, once we make all these connections things are kind of springy and surely the coils are not in their perfect place. The connections we made and all that wire around the inside is sure to push some of the coils out further than they ought to be.

How many ohms is a coil?

A typical coil is about 1-2 ohms. Connecting it directly to a 12v battery will usually result in something we don't like to see in electronics, smoke. Need at least one diode in there, either line, the kits have been using the 1N5408. You can get them off of Amazon.

What is a charging coil?

1) Charging coils are intended to charge batteries while driving 12DC loads and are available in 1A, 3A and 7A. These are ~ twice the voltage of lighting coils to leave enough voltage after rectification. 2) Lighting coils are intended to power incandescent AC bulbs on vehicles without starters.

What type of flywheel do charge coils use?

3) Charge coils use the 3 magnet flywheel, Lighting coils use the 2 magnet flywheel.

Does a single diode charge a battery?

Not from me. The single diode method does charge the battery. My concern is that at Top Of Charge nothing is in place to bring the charge voltage down to 12.6 volts. Without it we have overheating.