- Insert the wire into the connector until the insulation touches the barrel. Carefully place the exposed portion of the wire into the connector.

- Place the barrel of the connector into the appropriate crimper slot. ...

- Squeeze the crimper over the barrel with considerable force. For manual crimpers, hold the tool perpendicular to the terminal and over the barrel—closer to the ring than the wire ...

- Solder the wire to the connector if the connection is loose. In some cases, the connection is left loose due to a wrong wire size or connector.

- Seal the terminal with electrical tape or heat shrink. Use a pair of scissors to remove a small piece of electrical tape big enough to cover the crimp terminal.

How do you crimp a 15 gauge wire?

Place 1⁄4 inch (0.64 cm) of the end of the wire into the crimping die. Locate the hole designated for your wire's gauge in the crimping die. For example, if you're crimping a 15-gauge red wire, select the hole designed for a range that covers this gauge range.

What are wire crimpers and how to use them?

Wire crimpers help you to crimp wires together tightly and consistently, so you can make a secure electrical connection and avoid the risk of corrosion and shorting out. So, if you want to learn how to crimp wires, you should know that there are two basic types of crimping tools: manual and hydraulic.

How do you crimp a wire with a crimping die?

Make sure that the amount of wire is approximately equal to the metal barrel of the connector, which is usually 1⁄4 inch (0.64 cm). Most crimping dies have color-coded holes that designate where to put specific colored wires. Pull the insulation away to expose the bare wire inside.

How to check the quality of the crimping terminals?

Measuring the crimping height of the crimped terminals at the center of the wire barrel and at the center of the insulation barrel, verify the crimp is within range specified by the manufacturer. This measurement of the height of the terminated wire in the crimp area is a good method of quality control as it is non-destructive.

How do you crimp a wire?

1:432:48How to Crimp Wires - Basic Tips on Crimping - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe end of the barrel. Then insert the wire and terminal into the crimper. If your crimping toolMoreThe end of the barrel. Then insert the wire and terminal into the crimper. If your crimping tool features colored markings match the insulation with the color on your crimping.

How do you crimp without a crimper?

0:001:40Crimping without a crimp gun - YouTubeYouTubeStart of suggested clipEnd of suggested clipThen need to strip about two millimeters of insulation. If it twists up the way splain up. And thenMoreThen need to strip about two millimeters of insulation. If it twists up the way splain up. And then insert it into the crimp approximately halfway if you feel carefully there are two pairs of crimps.

Can you crimp wires with pliers?

To achieve the necessary compressive force, it's best to use a crimping tool when attaching crimp connectors to a wire. Pliers or a hammer will work in a pinch, but using such tools can result in a loose connection that ultimately results in an open circuit.

How do you crimp a small wire?

9:2017:46The Challenges and Methods of Crimping Small Wires - YouTubeYouTubeStart of suggested clipEnd of suggested clipSupport should be snug. But not so tight as to cut into the insulation. The insulation support movesMoreSupport should be snug. But not so tight as to cut into the insulation. The insulation support moves the stress point of the wire back from the bare wire to the insulation.

What can I use instead of crimp tool?

If you are going to try it, use a small flat-head screwdriver to push down the pins into the wires. You will need to push down all 8 pins into the 8 wires. Before pushing down your pins make sure that all of the individual wires are completely pushed to the end of the jack.

Are there any alternative tools that can be used or replaced the crimping tool in locking the RJ 45?

If you don't have a crimping tool, no problem! Use a pair of scissors or a utility knife to cut away a section of the sheathing at the end of the cable, untwist and arrange the small cables in the right order, put them into the RJ-45 connector, and use a small, flathead screwdriver to press down each of the pins.

How do you crimp with regular pliers?

2:103:16How to crimp with pliers or a crimping tool using bead and tube crimpsYouTubeStart of suggested clipEnd of suggested clipAnd basically all you're going to do is crush your crimp so that it's flat you don't want to goMoreAnd basically all you're going to do is crush your crimp so that it's flat you don't want to go crazy. You don't want to damage your wire give it a good tug. And you're all set.

How do you make a crimping tool?

3:0917:21home made crimper for battery cables - YouTubeYouTubeStart of suggested clipEnd of suggested clipCut it in half you can see that cut it in half. And then on one side I made a little divot with aMoreCut it in half you can see that cut it in half. And then on one side I made a little divot with a step drill and then I found myself a ball bearing that fits right into this divot.

What can I use instead of crimp beads?

An alternative to crimp beads and crimp tubes is a newer finding called Screw-Tite Crimps™. Screw-Tite Crimps not only secure your Accu-Flex® beading wire to your clasp, they also allow you to change your clasp for a different one, should you want a different look.

How do you crimp like a pro?

7:019:12How To Crimp Like a Pro | TECHNICALLY SPEAKINGYouTubeStart of suggested clipEnd of suggested clipSo for this one we're going to be using the jewel number three using the blue. Crimpers. Nice andMoreSo for this one we're going to be using the jewel number three using the blue. Crimpers. Nice and tight. Now we're going to also be using draw. Number one which is going to crimp that right around.

How do you connect small wires without soldering?

3:046:11Join wires reliably with NO solder - YouTubeYouTubeStart of suggested clipEnd of suggested clipSometimes you can spin it a little bit with your fingers. To get it over top you want this prettyMoreSometimes you can spin it a little bit with your fingers. To get it over top you want this pretty tight. And then you're gonna push. The shrink tubing over so it's exactly centered.

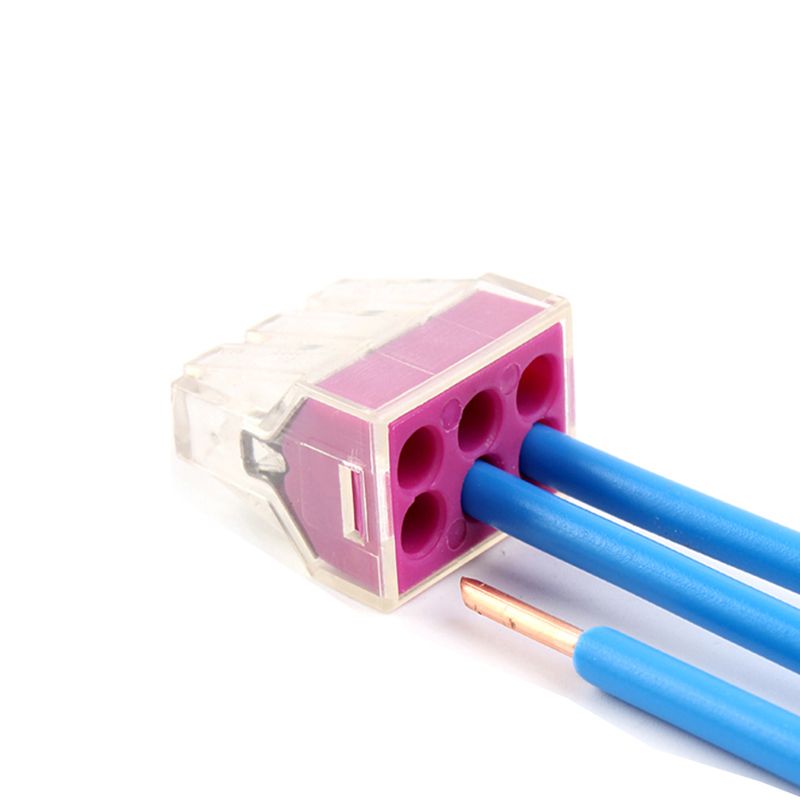

How do Jelly crimps work?

The small size of the UY connector reduces the splicing bundle O.D. to a minimum. The connector's two ports accept two solid copper conductors. The connector is filled with a sealant to provide moisture resistance.

What is crimping a wire?

Crimping is a common method for compressing a terminal to a wire conductor without the use of soldering. When done correctly, a crimp creates a mechanically sound connection that resists corrosion, gas, and liquids. If you’ve ever crimped a terminal to a wire, you know that it’s not the most glamorous of tasks.

Why use a crimp tool?

Many customers like using ratcheting crimp tools because they provide tactile feedback so you know when the terminal crimp is fully compressed. Ratcheting crimp tools also assure a proper crimp by providing a color coded, visual confirmation that you are using the correct cavity for the gauge wire you are crimping.

Why is crimping important?

The main benefit of crimping is that it eliminates the need for soldering wire, therefore reducing installation time. This reduction in time is very important in today’s market where time is of the essence and fewer technicians are being asked to maintain more and more equipment.

Buy a striper and a crimper

Prepare properly before starting the process. Arrange a stripper to strip off the insulation before you can think of crimping.

Strip your wire

Put at least ¼ inch of the wire into the die. It usually covers the metal part of the crimp. In a few tools, you might also find color gauges. They can help you in getting to the right gauge depending upon the color type.

Twist the wire

Once you have the wire exposed, hold it with your thumb and forefinger. Twist the tip of the wire on any side to make it firmer.

Attach it to the connector

By now, you’ll have your wire crimpled. Insert it into the connector until it reaches the barrel. Do not extend it more than 1/4th of the barrel.

Crimp

Put the terminal with the barrel facing upwards. Keeping the crimper perpendicular to the barrel, place the wire inside the gauge.